Amphenol D38999 G Class Series III Connectors with Vacuum Degassing

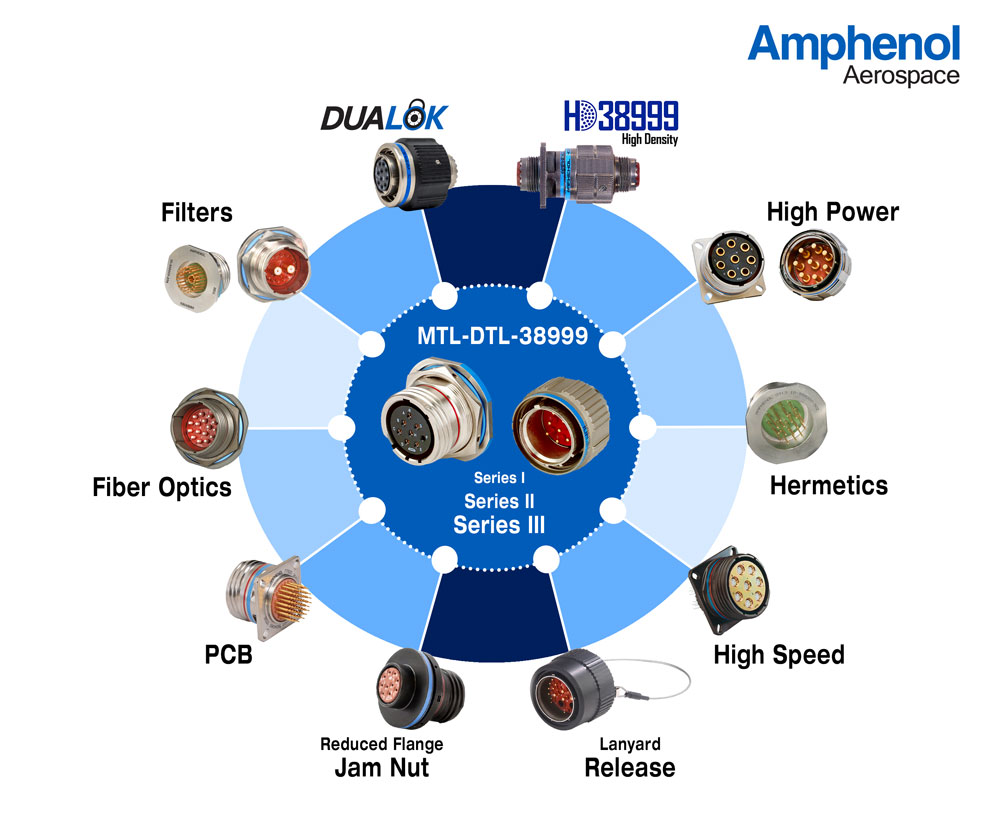

MIL-DTL-38999, otherwise known as D38999 or 38999, are high-density, circular connectors with threaded or bayonet coupling, available with crimp or solder contacts in various contact arrangements. D38999 connectors are designed for environmental resistance with an operational temperature range of −65 to +200 °C ( -85 to 392 °F) and are one of the most popular and widely used MIL-SPEC connectors on the market for both military and commercial aerospace applications due to their versatility and reliability.

There are several series of MIL-DTL-38999 connectors:

Series I

Series I connectors feature a bayonet coupling mechanism with a three-point bayonet locking system, allowing for quick connection and disconnect. They offer high contact density configurations and provide good environmental protection.

Series II

Series II connectors also use a bayonet coupling mechanism like Series I but come with enhanced features for improved performance such as improved vibration resistance and better environmental sealing. They offer high-density contact options and a five-key/keyway system to prevent misalignment, with a smaller form factor due to their low-profile construction.

Series III

Series III connectors use a threaded coupling mechanism, providing a secure connection with superior vibration resistance. They offer the highest contact density options and superior environmental sealing, including excellent resistance to moisture, dust, and other contaminants.

Amphenol doesn’t just offer connectors within standard MIL-SPEC boundaries; customization beyond MIL-SPEC standards to craft any interconnect solution to meet your unique needs is available through our 38999 Plus catalog. Whether it’s power connectors, signal connectors, or high-speed connectors, 38999 Plus presents a massive inventory of MIL-SPEC styles and options to overcome any interconnect challenges.

Vacuum Degassing

What is Vacuum Degassing?

Degassing (or gas-off) is required of connectors and other components in space applications. As the name implies, the connectors must go through a vacuum outgassing procedure to remove harmful materials, per rigorous NASA or military specifications.

Why is this important in space?

While these construction materials are normal on earth based applications, they can become extremely hazardous in a space vacuum environment. Chemical or organic substances trapped inside materials (plastic, glue, coatings, etc.) could evaporate in the vacuum of space and re-condense on a cooler surface. These surfaces might include optical or electronics components whose performance could be impaired or damaged by this surface condensation.

How is Degassing Accomplished?

Assembled connectors are "baked" at high temperature in a high-vacuum environment to evaporate and extract potentially harmful substances trapped inside the normal construction materials. Powell vacuum oven system can achieve a maximum operating temperature of 300°C (572°F) at 10-6torr vacuum range to meet the needs of any space qualification specification.

Does every connector distributor have this capability?

No. This is a very specialized value-added capability that Powell is pleased to offer its customers.

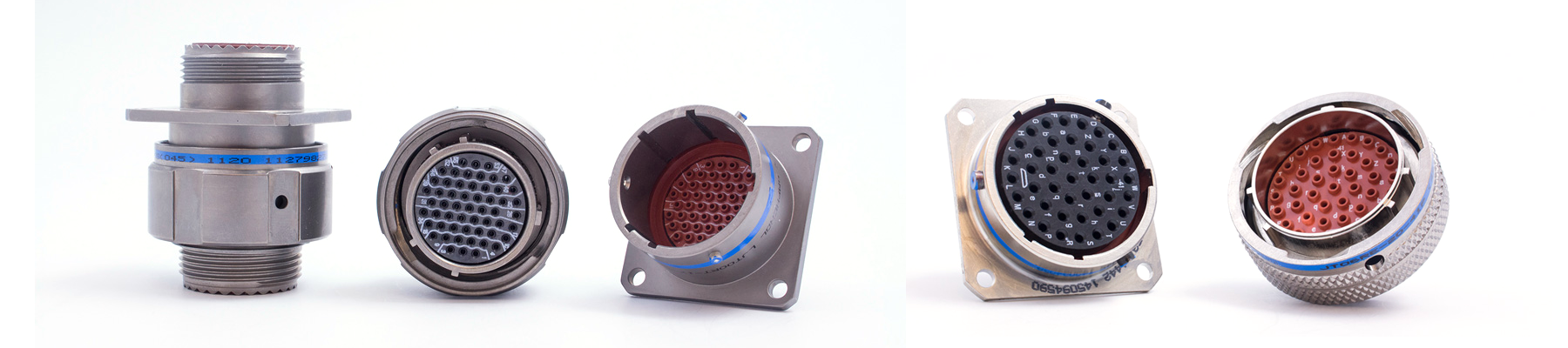

Product Images

Applications

- Military Aircraft

- Commercial Aircraft

- Naval Surface Ships

- Submarines

- Ground Vehicles

- Missile Systems

- Unmanned Vehicles

- Electric Military Vehicles

- Satellites

- Spacecraft

- Avionics Systems

- In-Flight Entertainment Systems

- Landing Systems

- Environmental Control Systems

- Fuel Management Systems

- Refueling Systems

- Power Distribution Systems

- Aircraft Braking Systems

- Communication Systems

- Cabin and Exterior Lighting

- Battery Management Systems